Mica: A Shimmering Marvel in the Marine Coatings Industry

The marine industry has long faced a challenging adversary: the relentless forces of water and salt. Keeping ships and vessels in optimal condition while protecting them from the harsh marine environment is no small feat. One crucial ally in this battle is mica, a naturally occurring mineral with extraordinary properties that make it an indispensable component in marine coatings. In this article, we’ll explore how mica is used in the marine coatings industry and why it’s considered a shimmering marvel.

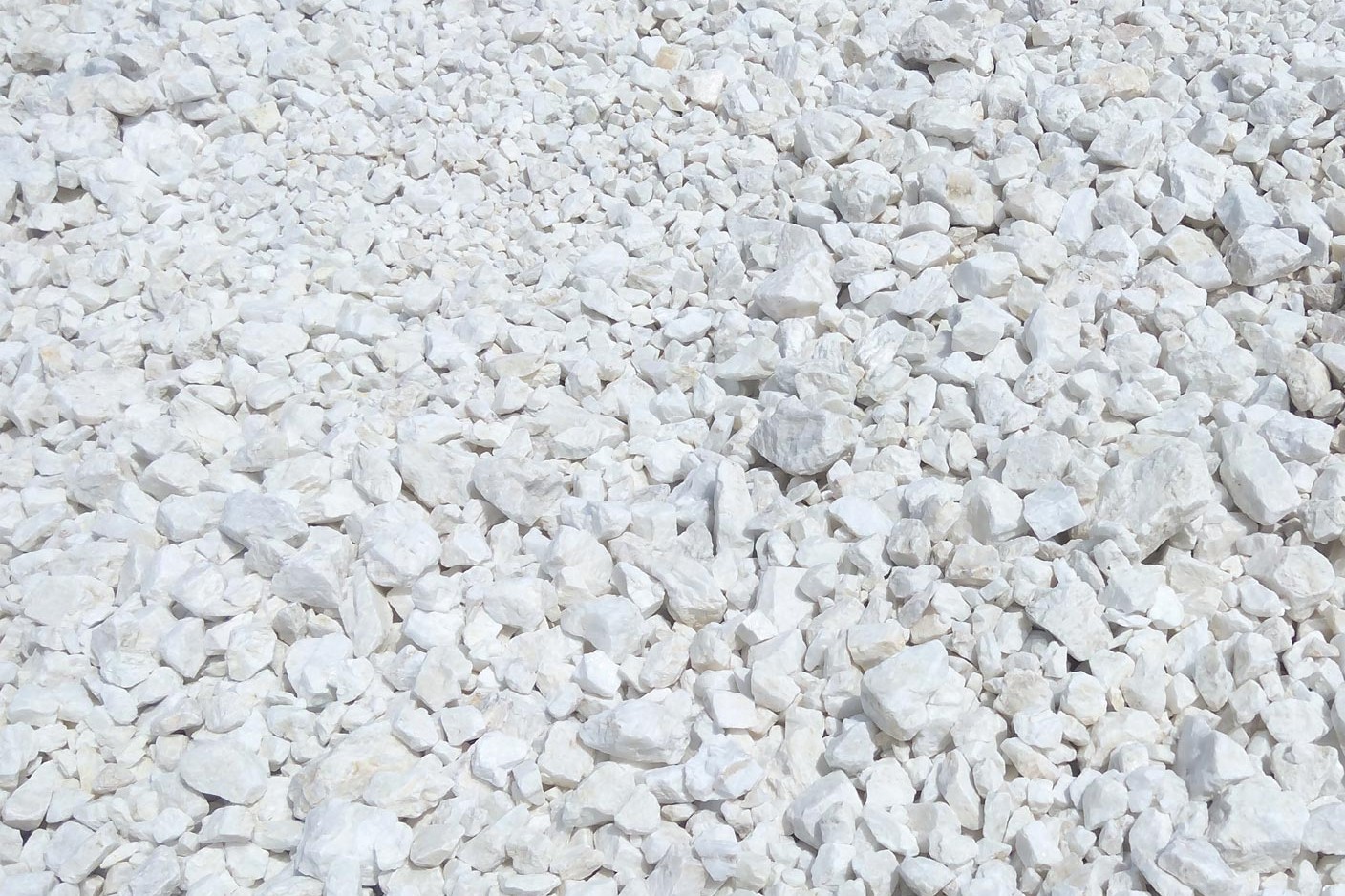

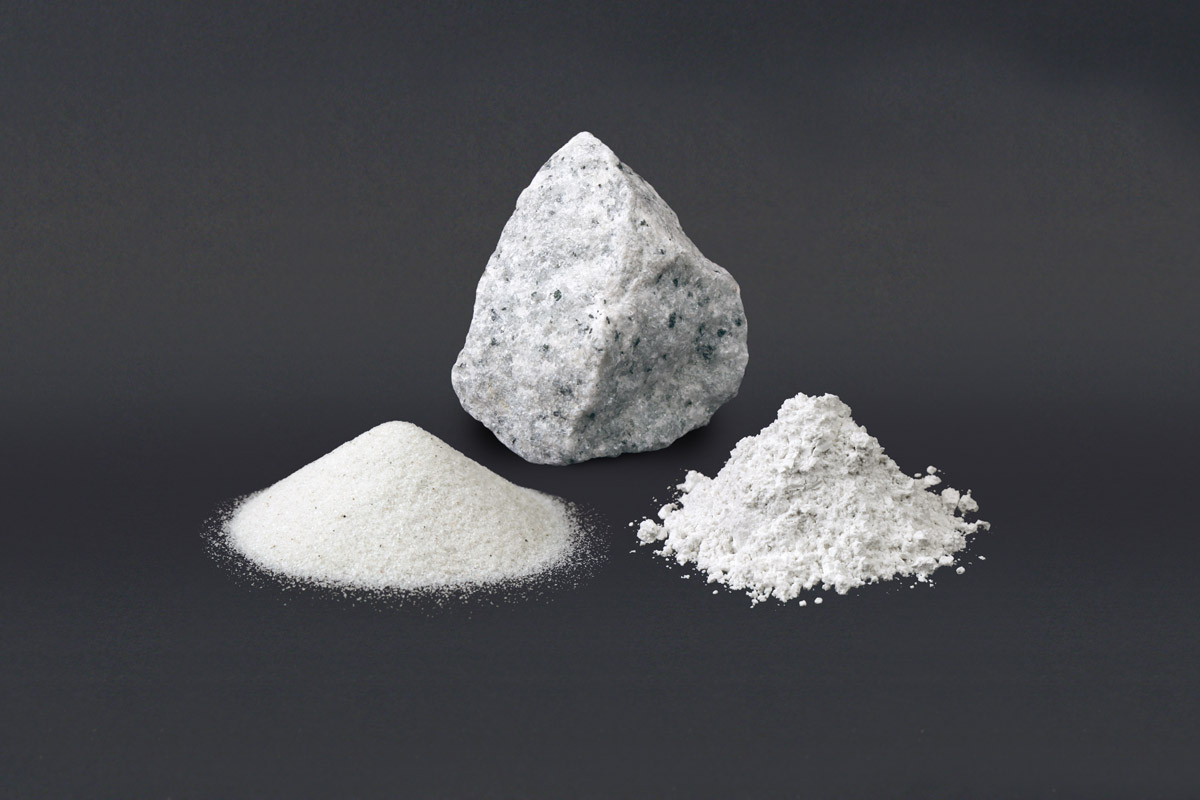

Understanding Mica

Mica is a group of silicate minerals characterised by its remarkable flexibility, resistance to high temperatures, and ability to split into thin, translucent sheets. Its unique properties make it highly sought after in various industries, including cosmetics, electronics, and, of course, marine coatings.

Mica in Marine Coatings

Enhancing Durability

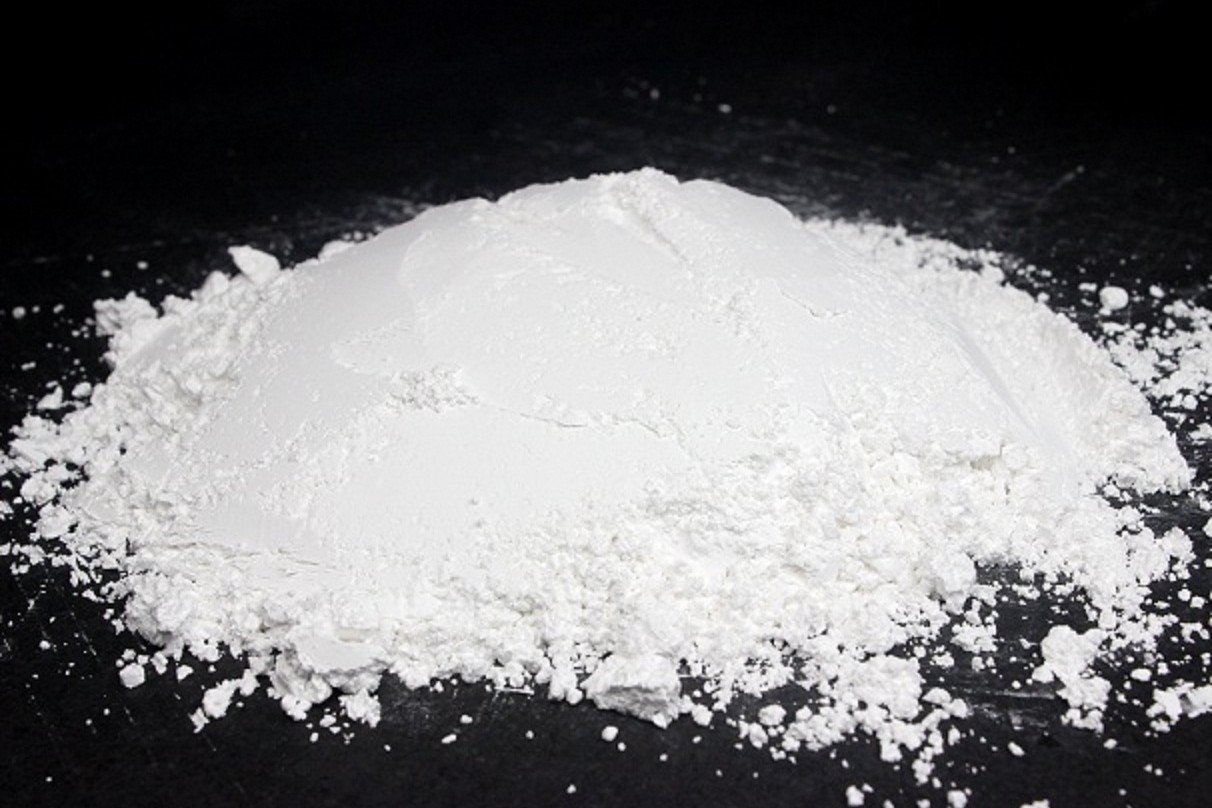

Mica’s exceptional resistance to moisture, corrosion, and UV radiation makes it an ideal additive for marine coatings. When incorporated into paint formulations, mica reinforces the coating’s durability, ensuring it can withstand the harsh marine environment.

Barrier Effect

Mica particles create a barrier within the coating, reducing the permeation of water, gases, and other corrosive substances. This barrier effect is crucial in preventing the deterioration of the ship’s surface over time.

Improved Adhesion

Mica’s unique surface properties enhance the adhesion of coatings to the substrate. This helps in achieving a strong, long-lasting bond, which is particularly important in marine applications where coatings are constantly exposed to water and mechanical stress.

Aesthetic Appeal

Beyond its protective qualities, mica also adds a shimmering, aesthetic dimension to marine coatings. The reflective properties of mica particles create a sparkling effect on the water’s surface, making ships and boats more visually appealing.

Applications of Mica in Marine Coatings

Antifouling Coatings

Mica is often used in antifouling coatings, which are applied to the hulls of ships to prevent the growth of marine organisms such as barnacles and algae. Mica-reinforced coatings create a smoother surface that is less prone to fouling, reducing hydrodynamic drag and improving fuel efficiency.

Corrosion-Resistant Coatings

Mica is a key component in corrosion-resistant coatings for both the interior and exterior surfaces of marine vessels. These coatings protect the underlying metal from rust and degradation caused by exposure to saltwater and humidity.

Topside Coatings

For the topside areas of ships and boats that are exposed to sunlight, rain, and seawater, mica-enhanced coatings offer superior protection against UV damage and colour fading, maintaining the vessel’s appearance over time.

Environmental Considerations

Mica, as a naturally occurring mineral, is generally considered environmentally friendly. Its use in marine coatings contributes to the longevity of ships and boats, reducing the need for frequent repainting and the associated waste of resources. Additionally, mica-reinforced coatings can improve fuel efficiency, indirectly reducing a vessel’s carbon footprint.

Mica’s remarkable properties have made it a valuable and versatile component in the marine coatings industry. Its ability to enhance durability, protect against corrosion, and add aesthetic appeal to vessels has earned it a prominent place in the world of maritime protection. As we continue to explore innovative solutions to safeguard ships and boats against the relentless forces of the sea, mica remains a shimmering marvel that plays a vital role in maintaining the integrity and beauty of the vessels that navigate our oceans.