Cenospheres

Cenospheres have the following areas of application;

- Cementing

- Plastics

- Construction

- Automobiles

- Ceramics

Cenospheres offer the following utility:

- Cost Efficient

- Low Density

- High Strength

- Improved Flowability

- Low Shrinkage

- Thermal Stability

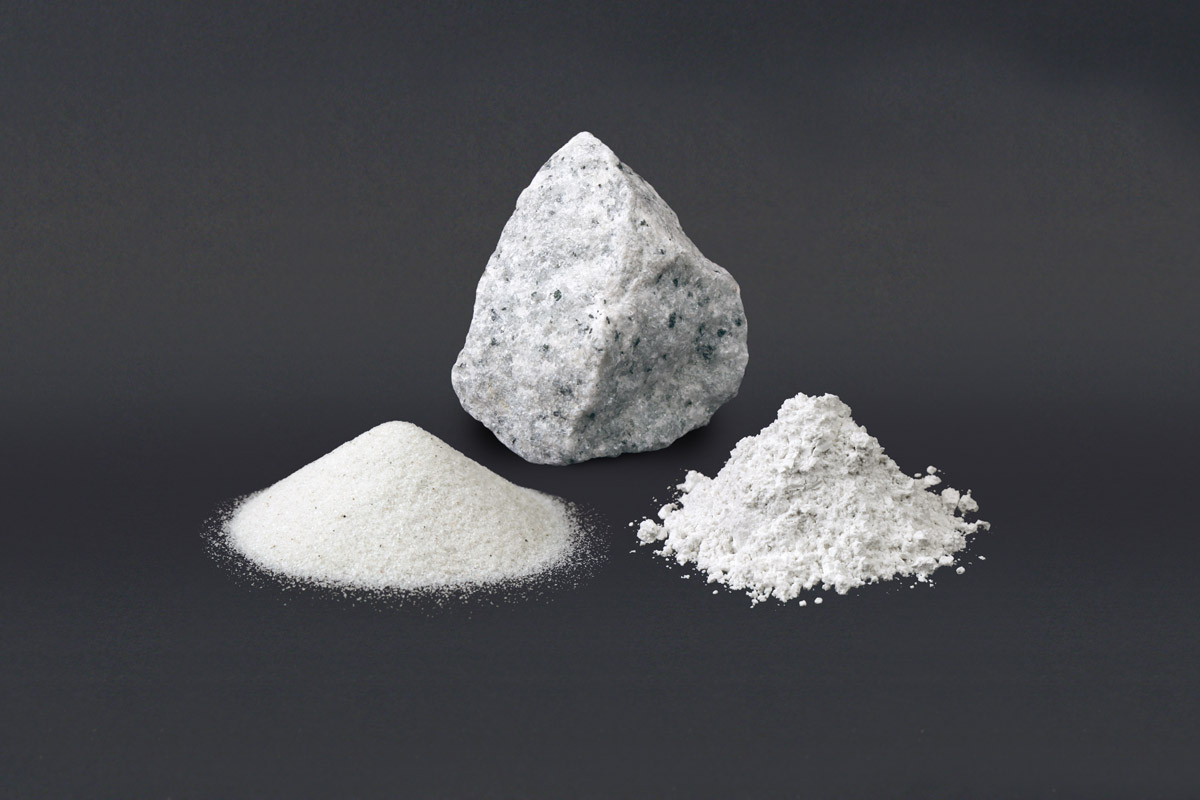

Cenospheres are marketed in various grades according to the following specifications:

- Crushing Strength Density

- Size

This spherical shape of Cenosphere allows flowability low surface area- to-volume ratio. Due to this it provides even distribution of the filler material.

Being inert it is not affected by solvents, water, acids of alkalis. Cenospheres are 70% lighter than other minerals which are being used as filler.

Utilisation of cenosphere reduces the cost of the final product and at the same time improves strength and durability.

Specification

Physical Properties

| Specific Gravity | 0.70 - 0.80 G/CC |

| Bulk Density | 400 - 450 KGS/CBM |

| Hardness (MOH) | 5 - 6 |

| Compressive Strength | 180 - 280 KGS/CBM |

| Shape | Spherical |

| Packing Factor | 60 - 65% |

| Wall Thickness | 5 - 10% of Shell Diameter |

| Colour | Light Grey, Light Buff |

| Melting Point | 1200 - 1300 oC |

| Thermal Conductivity | 0.11 WM-1k-1 |

| PH In Water | 6 - 7 |

| Moisture | 0.5% Max |

| Loss on Ignition | 2% Max |

| Sinkers | 3% Max |

| Oil Absorption | 16 - 18g/100g |

Chemical Properties

| All Grades | |

| SiO2 | 52% - 62% |

| Al2O3 | 30 - 36% |

| CaO | 0.1 - 0.5% |

| K2O | 1.2 - 3.2% |

| Fe2O3 | 1.0 - 3.0% |

| TiO2 | 0.8% - 1.3% |

| MgO | 1.0% - 2.5% |

| Na2O | 0.2% - 0.6% |

| CO2 | 70% |

| Nitrogen | 30% |

Sieve Analysis

| APC30 | APC60 | APC85 | APC100 | APC120 | APC150 | APC30-150 | |

| +30 # (500 Micron) | 0 - 1% | NIL | NIL | NIL | NIL | NIL | 0 - 1% |

| +60 # (250 Micron) | 10 - 35% | 0 - 1% | NIL | NIL | NIL | NIL | 10 - 35% |

| +100 # (150 Micron) | 40 - 80% | 20 - 70% | 1% Max | NIL | NIL | NIL | 40 - 80% |

| +150 # (106 Micron) | 70 - 90% | 50 - 80% | 0 - 30% | 0 - 5% | 0 - 5% | 0 - 10% | 70 - 90% |

| +240 # (63 Micron) | 85% - 95% | 75 - 95% | 20 - 70% | 35 - 75% | 35 - 75% | 70 - 95% | 85 - 95% |

| -240 # | 0 - 10% | 0 - 20% | 0 - 20% | 0 - 20% | 0 - 20% | 0 - 30% | 0 - 10% |