Revolutionising Glass Production: The Remarkable Benefits of Nepheline Syenite

Nepheline syenite is an intriguing and valuable mineral in the glass-making industry, offering a range of benefits that make it an attractive alternative to traditional raw materials. This article explores the advantages of using nepheline syenite in glass production, highlighting its impact on the industry.

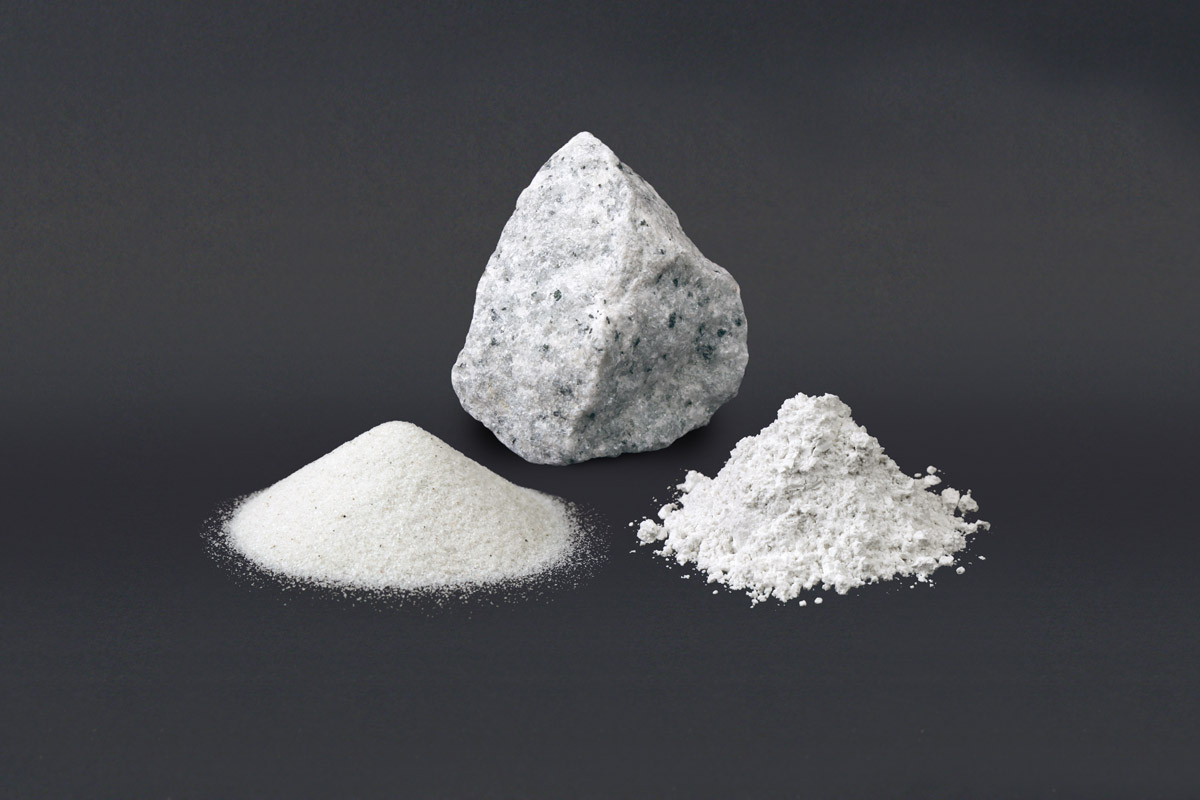

Introduction to Nepheline Syenite

Nepheline syenite is a plutonic rock, largely composed of nepheline and alkali feldspar. This mineral composition makes it a unique and beneficial additive in the glass-making process. It is mined in various parts of the world, including Canada, Russia, and Norway, and has been increasingly recognised for its utility in industrial applications, particularly in glass and ceramics.

Benefits of Nepheline Syenite in Glass Making

Lower Melting Temperature

One of the primary advantages of nepheline syenite is its ability to lower the melting temperature of glass batches. The presence of alkali metals in nepheline syenite acts as a flux, reducing the energy required to melt silica, the primary component of glass. This reduction in melting temperature translates to significant energy savings during production, making the glass-making process more efficient and environmentally friendly.

Improved Chemical Durability

Glass products made with nepheline syenite exhibit enhanced chemical durability. This is particularly beneficial for glass containers and other products that require resistance to weathering and chemical corrosion. The alkali and alumina content in nepheline syenite contributes to the formation of a glass matrix that is less prone to degradation, extending the lifespan of the products.

Enhanced Physical Properties

Incorporating nepheline syenite into glass batches can also improve the physical properties of the final product. Glass made with nepheline syenite tends to have a lower coefficient of thermal expansion, making it more resistant to thermal shock. This is crucial for glass items that undergo rapid temperature changes, such as cookware and laboratory equipment.

Reduced Emissions

The use of nepheline syenite in glass production can lead to lower carbon dioxide emissions. Since the material lowers the melting point of the glass batch, less energy is required for melting, which in turn reduces the carbon footprint of the manufacturing process. This makes nepheline syenite an attractive option for industries aiming to minimise their environmental impact.

Cost Efficiency

Lastly, the incorporation of nepheline syenite can contribute to cost savings. Its role in lowering the melting temperature not only reduces energy consumption but can also extend the life of furnaces and related equipment due to less wear and tear. Moreover, the use of nepheline syenite can reduce the need for other, more expensive raw materials, making the glass-making process more cost-effective overall.

Summary

Nepheline syenite offers a multitude of benefits for the glass-making industry, from energy savings and environmental advantages to improvements in the durability and physical properties of the glass. Its use exemplifies how natural minerals can be leveraged to enhance industrial processes, making them more efficient, sustainable, and cost-effective. As the industry continues to evolve, the role of nepheline syenite in glass production is likely to expand, further underscoring its significance in the sector.